Laying hens have a good grasp of cooling and nutrition

- Published in Chicken cages

- Be the first to comment!

- Read: 1766 times

Heatstroke prevention and cooling measures, heat insulation and cooling. The roof of the chicken house is covered with a layer of asbestos tile, which is both rainproof and has good heat insulation effect; the wall around the chicken house is coated with lime water, which can effectively disinfect and reduce the temperature of the house. Do a good job of greening. Planting tall and broad-leaved trees 2 to 3 meters away from the chicken house, you can avoid direct sunlight in the house; you can also plant vine climbing plants, such as ivy, morning glory, etc., not only to absorb sunlight, The effect of sunshade and summer heat can also increase oxygen production, reduce dust and improve the microclimate environment of the chicken house.

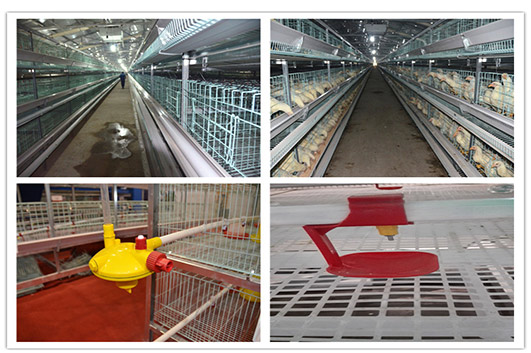

Increase ventilation. Good ventilation is an important measure to ensure the environment inside the house. In the summer, under the premise of ensuring safety, all doors and windows will be opened, ventilation devices such as exhaust fans and ceiling fans will be activated, and facilities and obstacles that hinder air circulation will be removed, and the flow of air in the house will be maximized to reduce the temperature. Conditional ventilation can also be used, that is, ventilation along the longitudinal axis of the house, the cooling effect can reach 5 ° C ~ 8 ° C. Shearing heat. The chicken has rich feathers, no sweat glands on the skin, strong warmth and poor heat dissipation. In summer, the chickens are cut at the right time to increase the egg production rate. Spray water to cool down. You can often use cold water to cool and cool down. When the temperature exceeds 32 °C, you can use a rotary sprayer to spray cold water on the top or wall of the house or cool down the cold water spray. Generally, the temperature can be lowered by 5 °C~10 °C. .

In order to ensure that the high-heat summer egg hens intake enough nutrients, the breeder should adjust the diet structure in time. Nutritional formula. During the hot season, the feed intake of chickens is reduced, and insufficient nutrient intake directly hinders egg production. In order to better meet the nutritional needs of chickens in different stages of egg production, we should feed more high-protein diets in the morning and evening, and feed more green and juicy feeds at noon and diversify the feed varieties in poultry farm equipment manufacturers in mumbai.

Increase vitamins. In summer, laying hens are particularly susceptible to vitamin deficiency due to heat stress, so the multivitamin content in the diet should be increased. Generally, in the hot summer, the amount of multivitamins can be increased by 2 to 3 times, especially vitamin C, which can significantly alleviate heat stress.