The impact of poultry farming equipment on egg production in South Africa

- font size

- Be the first to comment!

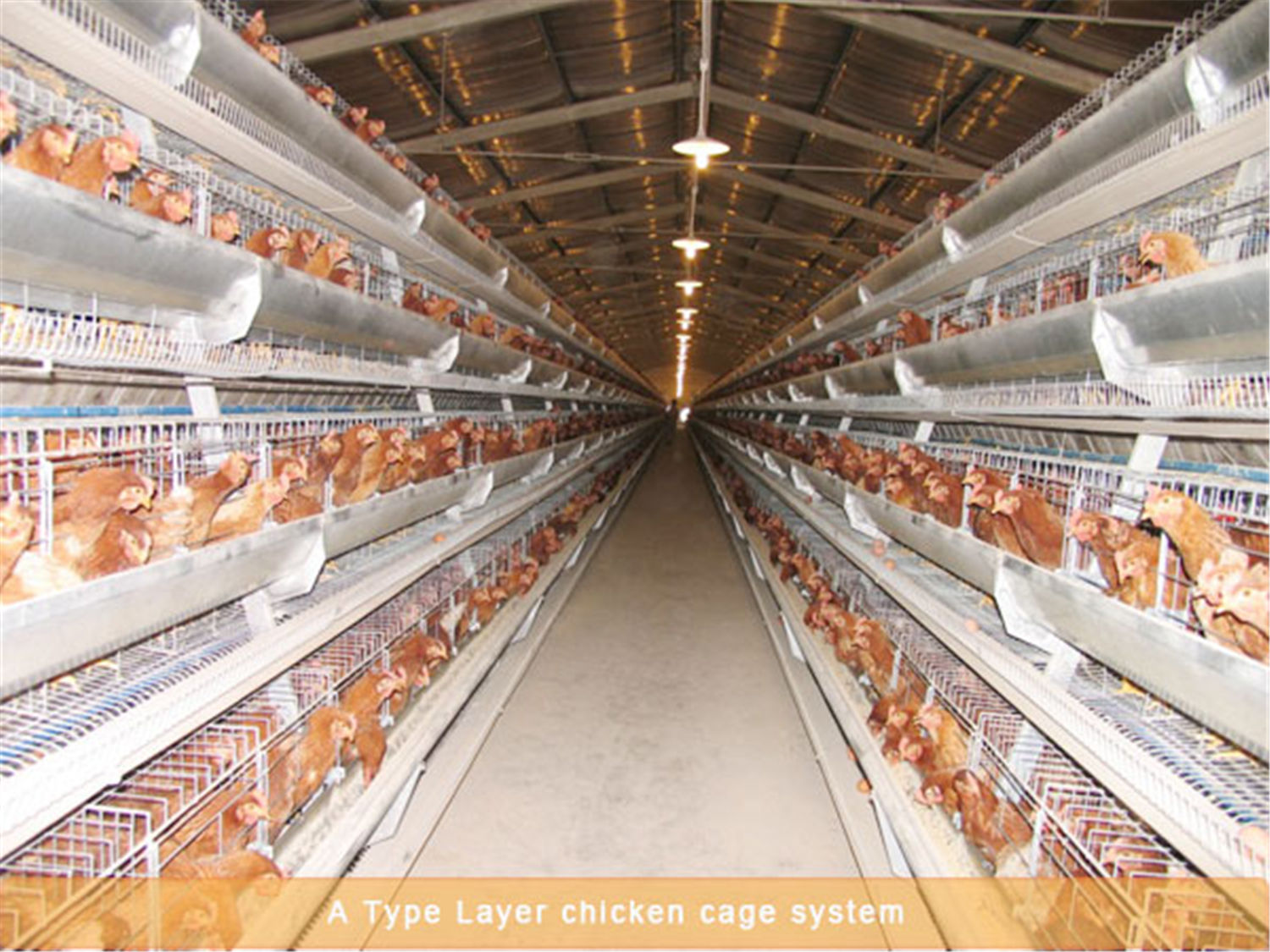

Different poultry farming equipment in South Africa has different effects on egg production when used. For example, in the process of laying eggs, some eggs may be damaged. Such damaged eggs are easily damaged during storage, and the contents that flow out may contaminate the undamaged eggs.

- First of all, because laying hens are produced in cage nets. Therefore, the quality of the cage net itself has a greater impact on the egg breaking rate. For example, if the grade of some steel wire materials is too low, the elongation rate of the steel wire is too high, and the steel wire is too soft, which will lead to the peak of egg production in an egg laying cycle. The amount has already reached the limit weight. This waits until the load-bearing capacity of the bottom net of the chicken layer cages has reached the limit value. It is inevitable that the bottom net of the chicken coop will sag, and there will even be deep foot sockets where the chicken feet stand. This will cause the egg to fail to roll out and be trampled by the chicken and collided with the egg.

- So in fact, the chicken battery cagesare also very important when designing. In the design, it is generally necessary to design according to some production characteristics of the laying hen itself. Especially in recent years, some internationally advanced poultry farming equipment production technologies have been introduced into the market. This also plays a very important role in advancing the design of chicken layer

- The chicken cage mesh in the automated poultry breeding equipment should be of high quality. This will not only reduce the egg breaking rate, but also help the laying hens grow healthily in thechicken battery cages.

Published in Poultry raising equipment