benefits of using automatic layer chicken cage equipment

- Published in Chicken cages

- Be the first to comment!

- Read: 1600 times

Optimizing Space Utilization in Poultry Houses

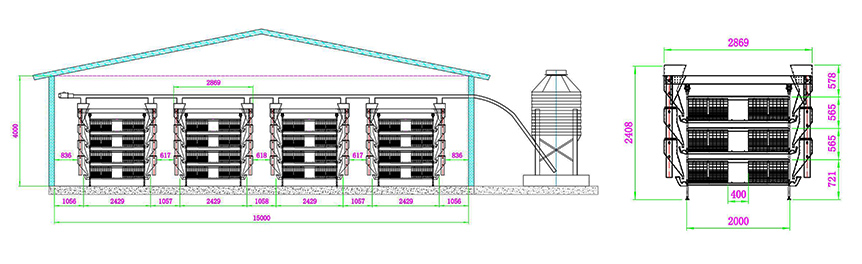

Maximizing the efficiency of your poultry house is crucial. With 10,000 brooder cages, consider a modular setup that allows for easy expansion and reconfiguration. For example, a 200x100 ft chicken house can house up to 500 cages, optimized with stacking designs to use vertical space. Leveraging space effectively not only enhances operational efficiency but also ensures better management of feed and waste.

2. Enhancing Chick Growth with Advanced Cages

Investing in high-quality brooder cages, like those from LIVI, can significantly impact chick growth and health. LIVI’s cages are designed to provide optimal conditions for chicks, promoting faster growth and reducing mortality rates. These cages often include features such as adjustable heating systems and easy-access feeding and watering stations, which are critical for nurturing healthy chicks.

3. Efficient Cage Placement Strategies

Strategically placing brooder cages within your poultry house can optimize airflow and lighting, essential for chick development. Positioning cages in rows with ample space between them facilitates easy movement and access for cleaning and monitoring. Implementing a grid layout can also help in maintaining consistent temperature and humidity levels across the poultry house.

4. Project Case Study: Success with LIVI Equipment

Consider the example of a recent project where a Ugandan poultry farm implemented 10,000 LIVI brooder cages in a newly constructed 300x150 ft facility. The cages were arranged in a tiered system to maximize space. Within six months, the farm reported a 25% increase in chick survival rates and a noticeable improvement in overall flock health, attributed to the advanced features of LIVI cages.

5. Long-Term Cost Benefits of Quality Cages

Investing in durable, high-quality brooder cages reduces long-term costs associated with maintenance and replacements. LIVI’s cages, known for their robust construction and energy efficiency, offer significant savings over time. The initial investment in quality equipment pays off through lower operating costs and higher productivity.

6. Upgrading to Modern Poultry Equipment

For farms currently using outdated equipment, upgrading to modern brooder cages can revolutionize operations. LIVI provides state-of-the-art cages that incorporate the latest technology in poultry farming. This upgrade can lead to more efficient management of chicks, improved environmental control, and ultimately, a more profitable operation.

By exploring these angles, poultry farmers in Uganda can make informed decisions about purchasing brooder cages and see significant improvements in their poultry farming practices.

Managing a poultry house equipped with automatic layer cages in Mexico presents a unique set of challenges and opportunities. With advancements in technology, these systems have become increasingly popular among poultry farmers, offering increased efficiency, improved animal welfare, and optimized production yields. Here's a comprehensive guide on how to effectively manage such a poultry house in Mexico.

1. Understanding the System Basics

First and foremost, it's crucial to have a solid understanding of the automatic layer cage system. These systems typically consist of stacked cages designed to house hens in a controlled environment, with automated feeding and watering mechanisms. In Mexico's climate, it's important to ensure the system is equipped to withstand high temperatures and humidity, as well as to maintain proper ventilation and lighting for the hens' well-being.

2. Regular Maintenance and Cleaning

Maintaining a clean and hygienic environment is paramount in poultry farming. Regular cleaning of the cages, feeders, and waterers is essential to prevent the spread of diseases and ensure the health of your flock. Develop a schedule for daily, weekly, and monthly cleaning tasks, and ensure all staff are trained on proper cleaning protocols.

3. Monitoring and Adjusting Environmental Conditions

Automatic layer cages come with various sensors that monitor temperature, humidity, and air quality within the poultry house. Regularly check these readings and adjust the environmental conditions as needed to maintain optimal comfort for the hens. In Mexico's hot and humid climate, this may involve using fans, misting systems, or adjusting ventilation rates.

4. Managing Feed and Water Supply

Ensuring a consistent and balanced feed supply is crucial for optimal egg production. Use high-quality feeds tailored to the hens' specific needs and adjust the feeding schedule according to their production cycle. Similarly, ensure a constant supply of clean, fresh water by regularly checking and cleaning the waterers.

5. Monitoring Egg Collection and Handling

Automatic layer cages often come with egg collection systems that greatly simplify the egg-gathering process. However, it's still important to regularly check the collection belts and trays for broken eggs or debris, and to promptly remove any eggs from the system to prevent contamination. Implement proper egg handling procedures to ensure the quality and safety of your products.

6. Disease Prevention and Control

Regularly inspect the hens for signs of illness or stress, and immediately isolate and treat any sick birds. Implement biosecurity measures, such as limiting visitors, disinfecting equipment and clothing, and controlling pests and rodents, to prevent the spread of diseases. Keep accurate records of vaccination schedules and treatment histories to ensure the health of your flock.

7. Staff Training and Management

A well-trained and motivated staff is key to the success of any poultry operation. Ensure all staff members receive proper training on the operation and maintenance of the automatic layer cage system, as well as on animal handling, health, and safety protocols. Develop clear communication channels and a positive work environment to foster teamwork and collaboration.

8. Continuous Improvement and Innovation

Stay informed about the latest advancements in poultry farming technology and consider implementing new practices or technologies that can improve the efficiency and sustainability of your operation. Keep track of production data and analyze trends to identify areas for improvement and make informed decisions about your business.

In conclusion, managing a poultry house with automatic layer cages in Mexico requires a comprehensive approach that addresses the unique challenges and opportunities of the region. By focusing on maintenance, environmental control, feed and water management, egg collection and handling, disease prevention, staff training, and continuous improvement, you can optimize production yields, improve animal welfare, and ensure the long-term success of your poultry farm.

Poultry farming is a significant sector in Nigeria's agricultural landscape. With a growing demand for poultry products, many entrepreneurs are venturing into this field. However, understanding the costs involved, especially for poultry equipment, is crucial for setting up a successful farm. This article will explore the cost of poultry farm equipment in Nigeria, focusing on layer cage equipment, broiler cage equipment, and other essential tools.

When setting up a poultry farm, having the right equipment is essential for efficiency and productivity. The cost of poultry equipment can vary significantly based on the type, quality, and supplier. Here are some common types of poultry equipment for sale in Nigeria:

Layer Cage Equipment: These cages are designed for egg-laying hens, providing a structured environment that maximizes egg production.

Broiler Cage Equipment: These cages are meant for raising broiler chickens, ensuring optimal growth conditions.

Feeders and Drinkers: Essential for providing food and water to the poultry.

Incubators: Used for hatching eggs.

Brooders: Provide a warm environment for young chicks.

Manure Removal Systems: Help in maintaining cleanliness and hygiene in the farm.

Investing in Battery Layer Chicken Cages for sale in Zimbabwe offers several advantages to poultry farmers. Here's a breakdown of the benefits:

Increased Productivity: Battery cages are designed to maximize egg production by providing a controlled environment for the chickens. The cages are typically equipped with features that promote consistent laying, such as adequate lighting and comfortable perches. This leads to higher productivity rates compared to traditional free-range or open-floor housing systems.

Improved Hygiene: The enclosed nature of battery chicken cages helps maintain cleanliness, which is crucial for preventing the spread of diseases among the flock. The cages often come with integrated waste collection systems that make it easier to keep the environment clean and hygienic.

Labor Efficiency: Automated systems for feeding, watering, and waste management reduce the manual labor required to care for the chickens. This not only saves time but also minimizes the risk of human error during routine tasks.

Space Utilization: Battery cages are vertically stacked, allowing for efficient use of space within a poultry house. By utilizing vertical space, farmers can house more chickens in a given area compared to floor-based systems.

These benefits contribute to a more sustainable and profitable poultry operation. However, it's important for farmers to consider factors such as the initial investment cost, ongoing maintenance, and the welfare of the chickens when deciding whether to invest in battery layer chicken cages.

In the poultry industry, battery cages are commonly used for raising egg-laying hens. This article aims to provide a comprehensive analysis of the cost of battery laying hen cages in Zimbabwe for a farm with 10,000 chickens. We will explore the various aspects that contribute to the overall cost, including the cage price, installation expenses, and ongoing maintenance costs.

The cost of battery cages in Zimbabwe can vary depending on several factors, including the quality of the cages, the materials used, and the supplier. It is essential to consider the durability and functionality of the cages when determining the price. The average cost of battery laying hen cages in Zimbabwe for a farm with 10,000 chickens can range from $10,000 to $20,000 .

In addition to the cage price, there are installation expenses to consider. These expenses include the cost of labor, equipment, and any necessary modifications to the farm infrastructure. The installation process involves setting up the cages, ensuring proper ventilation and lighting, and establishing a feeding and watering system. The installation expenses can vary depending on the complexity of the farm layout and the availability of skilled labor. It is advisable to consult with experts or suppliers to get accurate estimates for installation costs .

Once the battery laying hen cages are installed, there are ongoing maintenance costs to consider. These costs include regular cleaning and disinfection of the cages, replacement of worn-out or damaged parts, and routine inspections to ensure the cages are in good condition. It is important to budget for these maintenance costs to ensure the longevity and efficiency of the cages. The exact maintenance costs will depend on factors such as the size of the farm, the number of cages, and the frequency of maintenance activities .

When calculating the cost of battery cages for a 10,000 chickens farm in Zimbabwe, it is important to consider other factors that may impact the overall expenses. These factors include transportation costs, import duties or taxes, and any additional equipment or accessories required for the cages, such as feeders and drinkers. It is advisable to consult with suppliers or industry experts to get a comprehensive understanding of all the costs involved

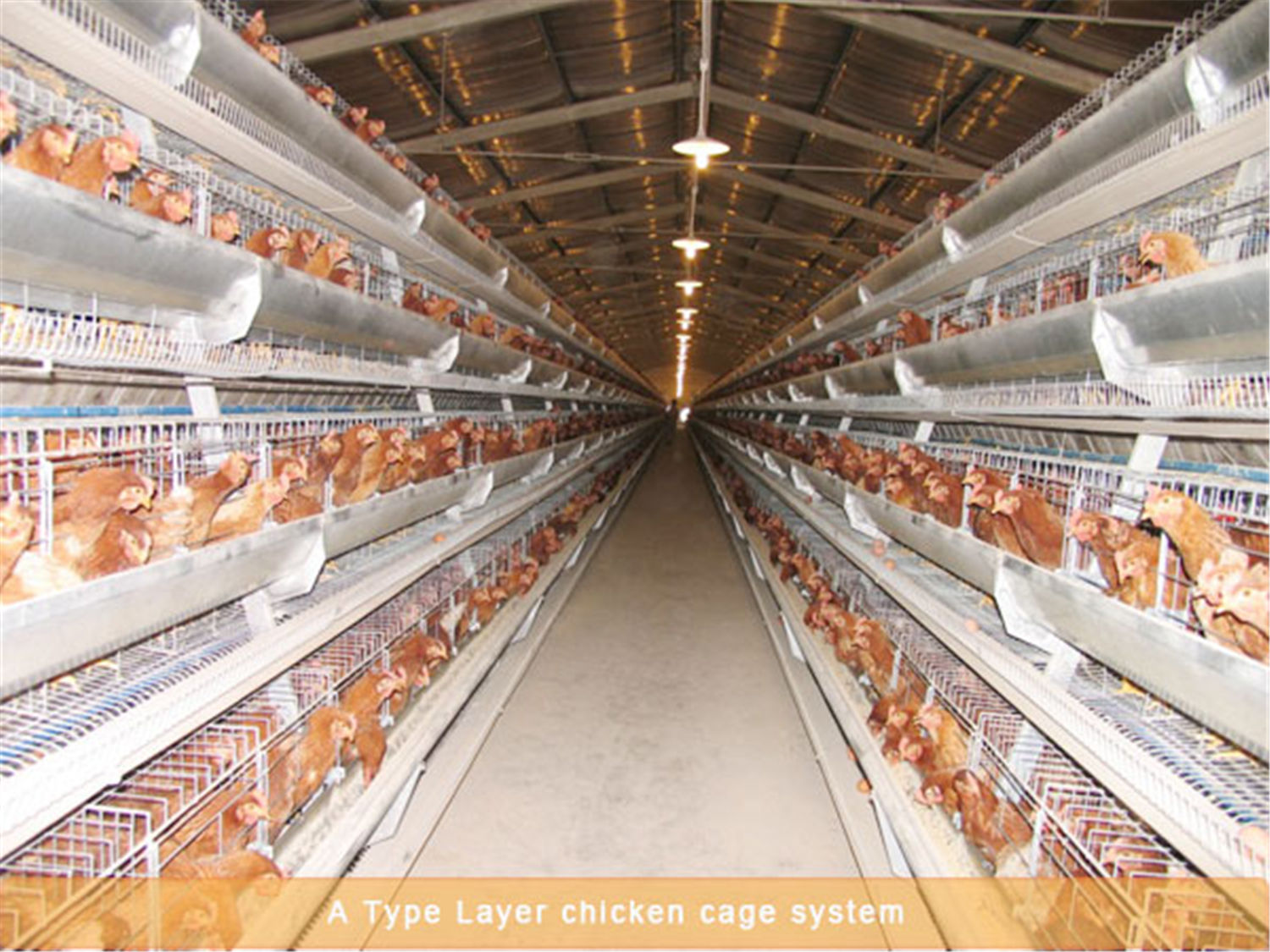

The battery chicken cage system is a popular choice for many farmers looking to efficiently raise chickens for egg production. This system involves housing chickens in stacked wire cages, allowing for high-density farming and maximizing space utilization. The cages are typically equipped with feeding and watering systems, as well as egg collection belts for easy access to the eggs.

One of the main advantages of the battery chicken cage system is its ability to streamline the management of a large number of chickens. The controlled environment allows for easier monitoring of the birds' health and behavior, while also minimizing the risk of disease transmission. Additionally, the system helps to reduce feed wastage and provides a cleaner and more hygienic living environment for the chickens.

Furthermore, the battery cage system can contribute to improved egg production efficiency. The controlled environment and easy access to feed and water can lead to higher egg yields compared to traditional free-range farming methods. This makes it an attractive option for farmers looking to maximize their egg production output.

However, it's important to note that there has been some debate about the welfare implications of housing chickens in battery cages. Critics argue that the confined living space and limited ability for natural behaviors can lead to stress and discomfort for the birds. As a result, there has been a growing trend towards alternative housing systems that prioritize animal welfare while still maintaining efficiency.

In conclusion, the battery chicken cage system remains a popular choice for many farmers due to its ability to efficiently manage a large number of chickens and maximize egg production. However, it's important for farmers to consider the welfare implications and explore alternative housing systems that prioritize both efficiency and animal well-being.

Galvanized chicken cages are widely used in poultry farming due to their durability, corrosion resistance, and long lifespan. However, there are two main methods of galvanization: cold-dip galvanizing and hot-dip galvanizing. Let’s talk about the differences between these two processes and provide some reference for poultry farmers when choosing to buy chicken cages.

1. Cold-Dip Galvanized Chicken Cages:

Cold-dip galvanizing, also known as electro-galvanizing, is a process that involves coating steel or iron components with a thin layer of zinc through electrolysis. In this process, the metal is submerged in a zinc electrolyte solution, and an electric current is passed through it to deposit zinc onto the surface. Cold-dip galvanized coatings are typically thinner and less durable than hot-dip galvanized coatings.

The service life is about 2-5 years. Many cold-dip galvanized chicken cages will have problems such as deformation and corrosion after one year of use.

2. Hot-Dip Galvanized Chicken Cages:

Hot-dip galvanizing is a process that involves immersing steel or iron components in a molten zinc bath at high temperatures. The metal is cleaned and pickled to remove any rust or impurities before being dipped into the zinc bath. As the metal is withdrawn from the bath, a thick layer of zinc forms on its surface through a metallurgical reaction, creating a strong bond between the zinc and the steel or iron substrate. Hot-dip galvanized coatings are thicker, more uniform, and more durable than cold-dip galvanized coatings. The service life is long, up to about 15-20 years. The overall structure is stable and not easy to deform and corrode.

3. Differences in Coating Thickness:

One of the key differences between cold-dip and hot-dip galvanized chicken cages is the thickness of the zinc coating. Hot-dip galvanized coatings typically have a thicker layer of zinc, ranging from 50 to 200 microns, compared to cold-dip galvanized coatings, which have a thinner layer of zinc, typically around 5 to 25 microns. The thicker coating of hot-dip galvanized cages provides superior corrosion protection and extends the lifespan of the cages, especially in harsh or corrosive environments.

4. Durability and Corrosion Resistance:

Due to the thicker and more uniform coating, hot-dip galvanized chicken cages offer greater durability and corrosion resistance than cold-dip galvanized cages. Hot-dip galvanized coatings provide a robust barrier against moisture, chemicals, and other environmental factors that can cause corrosion and deterioration over time. As a result, hot-dip galvanized chicken cages are better suited for long-term use in outdoor or high-moisture environments.

5. Competitive Pricing and Customer Preference:

At our company, we specialize in manufacturing hot-dip galvanized chicken cages that offer superior durability, corrosion resistance, and longevity. Despite the higher initial cost of hot-dip galvanizing compared to cold-dip galvanizing, our hot-dip galvanized chicken cages are competitively priced and offer excellent value for money. Customers prefer our hot-dip galvanized cages due to their exceptional quality, reliability, and longevity, making them the preferred choice for poultry farmers seeking long-term solutions for their housing needs.

In conclusion, while both cold-dip and hot-dip galvanized chicken cages offer corrosion protection and longevity, hot-dip galvanized chicken cages provide superior durability, corrosion resistance, and longevity due to their thicker and more uniform coating. Our hot-dip galvanized chicken cages are competitively priced and preferred by customers for their exceptional quality and reliability, making them the ideal choice for poultry farmers looking for long-lasting housing solutions for their flocks.

In the competitive world of poultry farming, maximizing productivity and profitability is crucial. One investment that can revolutionize your operation is the installation of 20,000 layers cages in an open chicken house. This innovative housing system offers a multitude of advantages that will elevate your farm to new heights.

1. Enhanced Bird Welfare and Increased Egg Production

20,000 layers cages are specifically designed to provide optimal living conditions for hens. Ample space, proper ventilation, and easy access to feed and water ensure their comfort and well-being. Studies have shown that hens housed in open cage systems exhibit reduced stress levels, leading to increased egg production and improved egg quality.

2. Efficient Space Utilization and Reduced Labor Costs

The compact design of layer cages allows you to maximize space utilization within your open chicken house. More birds can be accommodated in a smaller area, saving you valuable floor space for other farming activities. Additionally, the automated feeding, watering, and manure removal systems significantly reduce labor costs, freeing up your time for more strategic tasks.

3. Disease Control and Improved Hygiene

20,000 layers cages are designed to minimize the risk of disease transmission and promote hygiene in your poultry house. The isolation of individual birds prevents the spread of airborne pathogens, while the elevated cages reduce contact with contaminated litter. This helps maintain a healthier flock and reduces medication costs.

4. Reduced Feed Wastage and Increased Feed Conversion Efficiency

The feeding system in 20,000 layers cages is designed to minimize feed spillage and waste. Feed is delivered directly to the birds in troughs or nipple drinkers, preventing them from scratching or kicking feed out of the cages. This results in increased feed conversion efficiency, which means more eggs produced per pound of feed consumed.

5. Long-Term ROI and Sustainable Farming Practices

Investing in 20,000 layers cages is a long-term investment that will pay off over the years. The durable construction and corrosion-resistant materials ensure the longevity of the cages, providing years of reliable service. Moreover, the open cage system promotes natural ventilation and reduces the need for artificial lighting, contributing to more sustainable farming practices.

Why Choose Our Laying Hen Cages?

At poultry equipment supplier, we offer a comprehensive range of 20,000 layers cages designed to meet the specific requirements of open chicken house farming. Our cages are engineered with precision, using high-quality materials and cutting-edge technology, to garantire optimal performance and durability.

Here's what sets our cages apart:

Customizable Design: We understand that every farm is different, which is why we offer customizable cage designs to suit your specific needs. Whether you require a single-tier or multiple-tier system, we can tailor our cages to maximize space utilization and efficiency.

Innovative Feeding and Watering Systems: Our cages feature advanced feeding and watering systems that deliver feed and water directly to the birds with minimal spillage. This ensures optimal nutrition and hydration while reducing feed waste and labor costs.

Automatic Manure Removal System: Our cages incorporate an efficient manure removal system that automatically collects and transports manure to a designated storage area. This helps maintain a clean and hygienic environment for your birds, reducing disease risks and improving air quality.

Corrosion Resistance and Durability: Our cages are constructed using galvanized steel or stainless steel, ensuring corrosion resistance and longevity. They can withstand harsh weather conditions and repeated cleaning and disinfection, providing years of reliable service.

The role of ventilation and temperature control in battery chicken cages cannot be overstated when it comes to creating a conducive and healthy environment for layers. These factors play a crucial role in maintaining optimal conditions within the cages, directly impacting the well-being and productivity of the layers.

Proper ventilation is essential to ensure the circulation of fresh air and the removal of harmful gases. Battery chicken cages are designed with features that allow for adequate airflow, preventing the buildup of ammonia and other pollutants. Good ventilation not only enhances the respiratory health of the layers but also contributes to overall environmental hygiene.

Temperature control is equally important. Maintaining an optimal temperature within the cages is essential for the comfort and well-being of the layers. Battery chicken cages often incorporate temperature control features, ensuring that the climate remains within the suitable range for the birds. This is particularly crucial in extreme weather conditions, where temperature fluctuations can adversely affect egg production and layer health.

Effective ventilation and temperature control also contribute to disease prevention. A well-ventilated environment reduces the humidity levels, minimizing the risk of respiratory infections. Consistent temperature control prevents stress-related health issues among the layers, ensuring a more robust and resilient flock.

Farmers should actively monitor and adjust ventilation and temperature settings based on seasonal variations and specific farm conditions. Regular checks and maintenance of ventilation systems contribute to their effectiveness in creating a comfortable and healthy environment for layers.

In conclusion, understanding the role of ventilation and temperature control in battery chicken cages is essential for creating an environment that supports the well-being and productivity of layers. These features are integral components of modern poultry farming practices, ensuring a sustainable and efficient operation.

Poultry farming in Nigeria has witnessed a revolutionary shift with the advent of automatic battery chicken cages. As the demand for poultry products continues to soar, farmers are exploring innovative solutions to optimize production while ensuring the welfare of the birds. Are automatic battery chicken cages the key to achieving these goals?

These cages offer a sophisticated and automated approach to managing layers, providing a controlled environment that enhances egg production. For a poultry farm aspiring to house 10,000 layers, the implementation of battery cages becomes a crucial consideration. The cages not only optimize space utilization but also streamline daily operations, making them a practical choice for large-scale poultry farms.

One of the significant advantages of these cages is their ability to promote hygiene and disease control. The design ensures that waste is efficiently collected, preventing the buildup of harmful pathogens. Moreover, the automated feeding and watering systems contribute to a healthier flock, reducing the risk of contamination. This is particularly important in the context of Nigeria, where maintaining a disease-free environment is paramount for sustainable poultry farming.

The investment in Nigeria poultry equipment, specifically automatic battery chicken cages, proves to be a strategic move for farmers looking to scale up their operations. The controlled environment created by these cages not only increases egg production but also minimizes stress on the birds, resulting in improved overall welfare. As the agricultural landscape in Nigeria evolves, embracing modern technologies like automatic battery chicken cages might be the key to meeting the rising demand for poultry products.

In the dynamic world of poultry farming, staying ahead of the curve is essential to maximize productivity and animal welfare. For those looking to elevate their egg production operations, the availability of layer battery chicken cages for sale presents an opportunity to enhance both efficiency and bird well-being.

Layer battery chicken cages are specialized enclosures designed to house and manage laying hens in a controlled environment. These cages offer numerous advantages that make them a preferred choice for modern egg producers.

1. Space Optimization: Layer battery cages are built with a compact design, allowing you to make the most of your available space. With multi-tiered systems, you can effectively house a larger number of hens in a smaller footprint compared to traditional methods.

2. Improved Hygiene: Maintaining a clean and hygienic environment is crucial for the health of your birds and the quality of the eggs they produce. Battery cages are equipped with easy-to-clean surfaces and waste collection systems that simplify the task of waste management.

3. Enhanced Egg Collection: The design of layer cages facilitates easy access to eggs without disturbing the birds. This not only minimizes stress for the hens but also reduces the chances of egg breakage, resulting in higher egg quality.

4. Disease Control: Battery cages can be equipped with features like automatic feeding and watering systems, reducing the risk of disease transmission among birds. This ensures a healthier flock and minimizes the need for antibiotics.

5. Optimal Ventilation: Proper ventilation is essential for maintaining comfortable living conditions for the hens. Battery cages often come with built-in ventilation systems to regulate temperature and humidity, ensuring a conducive environment for egg-laying.

6. Streamlined Management: Battery cage systems are designed for efficient bird management. They enable easy monitoring of individual birds, feeding, and egg collection, allowing farmers to optimize their operations with precision.

7. Improved Animal Welfare: While there are ongoing discussions about the ethical concerns related to battery cages, modern designs prioritize the welfare of hens. Many cages are now equipped with features such as perches and nest boxes to enhance the birds' quality of life.

In conclusion, investing in layer battery chicken cages for sale can be a strategic move for poultry farmers aiming to boost their productivity while ensuring the well-being of their laying hens. By embracing these innovative cage systems, you can create a more efficient, sustainable, and profitable poultry farming operation. However, it's essential to stay informed about evolving industry standards and regulations to make ethical and responsible choices for your farm.

The adoption of battery chicken cages in Zambia poultry industry has sparked considerable discussion and transformation. This article explores the integration of battery chicken cages within Zambia's poultry farming landscape, examining their impact on production, efficiency, and the evolving dynamics of the agricultural sector.

Introduction to Battery Chicken Cages:

- Provide an overview of battery chicken cages, detailing their design and functionality within the context of poultry farming.

- Highlight their role in optimizing space and increasing egg production in a confined environment.

Implementation and Adoption in Zambia:

- Discuss the introduction and adoption of battery chicken cages within Zambia's poultry sector, exploring the reasons behind their integration and the response from farmers.

- Address the economic incentives and potential advantages driving their adoption in local poultry operations.

Impact on Poultry Production and Efficiency:

- Analyze the effects of battery chicken cages on poultry production metrics, such as increased egg yields and streamlined farming processes.

- Highlight efficiency improvements, cost-effectiveness, and potential challenges encountered by farmers utilizing this system.

Considerations for Animal Welfare and Ethical Concerns:

- Address the ethical considerations and discussions surrounding the use of battery chicken cages, focusing on the welfare of the birds within this confined system.

- Discuss efforts and initiatives aimed at balancing production demands with ethical treatment and well-being of the poultry.

Local Innovations and Best Practices:

- Showcase any local innovations or adaptations in the utilization of battery chicken cages in Zambia, emphasizing sustainability, bird health, and farmer well-being.

- Highlight best practices implemented by farmers to ensure optimal conditions for the chickens while maximizing production.

Regulatory Framework and Future Prospects:

- Examine the existing regulatory framework in Zambia concerning the use of battery chicken cages, discussing any guidelines or standards in place.

- Explore future prospects for the integration of alternative poultry farming systems and potential shifts in regulations.

Conclusion:

Battery chicken cages have emerged as a significant component of Zambia's poultry farming landscape, offering both opportunities and challenges. As the industry continues to evolve, balancing the need for increased production with ethical considerations will be pivotal for the sustainable growth of poultry farming in Zambia. This article sheds light on the impact, controversies, and future trajectories of battery chicken cages within the dynamic agricultural sector of Zambia.