Automatic feeding machine for animal husbandry chicken equipment

- Published in Chicken cages

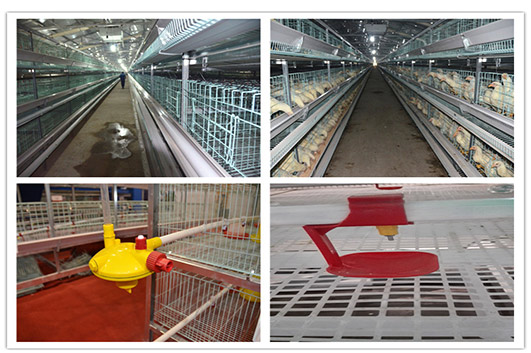

Poultry chicken farming equipment-automatic feeder is a mode of breeding chickens in cages, and a highly automated feeding equipment necessary for large-scale farms. The biggest feature of the feeder is that the feeding is uniform, saving time and effort. The feeder can feed three to five layers of chicken battery cages, which is convenient for cage raising and solves the problem of difficult feeding for farmers. The author will talk about some issues when using automatic feeders.

The automatic feeder has a traveling feeder mainly composed of driving components, that is, traction members, bins, and blanking tubes. The traction structure of the automatic feeder is characterized by the traction driving component installed at one end of the traveling track. The motor reducer will drive the material box along the track through the driving wheels and wire ropes to complete the feeding operation.

The traction drive unit is installed with the top bin, so that the bin is directly driven along the track by a sprocket. The automatic feeder can also complete the feeding operation. The installation condition of the chicken farm is that the distance from the pen to the house is more than 65 cm, and the space at both ends of the house must be above 2.2 meters. If the chicken farm wants to use fully automatic poultry breeding equipment, farmers need to ensure that the floor of the house is level and free of obstacles.

Read the instructions carefully before using the fully automatic feeder. To check the specifications of the chicken cage, understand the basic structure of the feeding cart and the operation of the buttons. The automatic feeding machine for the chicken farm can arrange the track in the middle of the sidewalk in the chicken house according to the required level, so that the positions of the sides of the feeding truck and the food trough can be guaranteed equal distances.

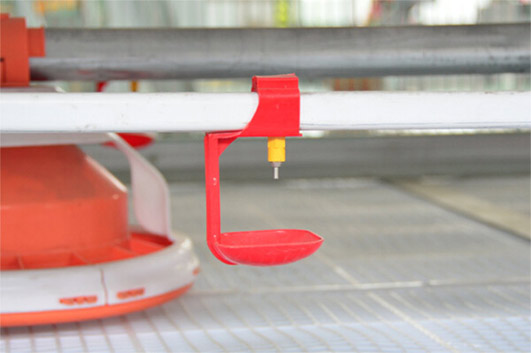

The feeding trough of the automatic feeder should be basically arranged to prevent the feeding effect from being affected when the feeding truck is feeding. When the power switch is set to open, the left and right augers are lifted at the same time, so that the discharge opening can be placed in the tank and the discharge opening is not long enough to be replaced. After the feeder places the feed in the silo, activate the left and right flour buttons and adjust the outlet button. This can make the discharge of the six outlets basically the same.

Turn off the left and right chicken buttons after adjusting. After turning down the governor switch of the feeding car, turn on the forward switch of the feeding car. You can adjust the speed switch box of the feeding car to the required operating speed, turn off the forward switch of the feeding car at the same time, and fix the speed regulating position, and turn off the power switch before feeding.