Requirements for building an intensive poultry farm in Nigeria

- Published in Chicken house management

Now buying battery cage system in Nigeria to carry out intensive poultry farming has become a rigid need for many farming friends. So what are the requirements for building an intensive poultry farm in Nigeria? Today, the poultry equipment factories will take you to understand.

Chicken Farm Space:

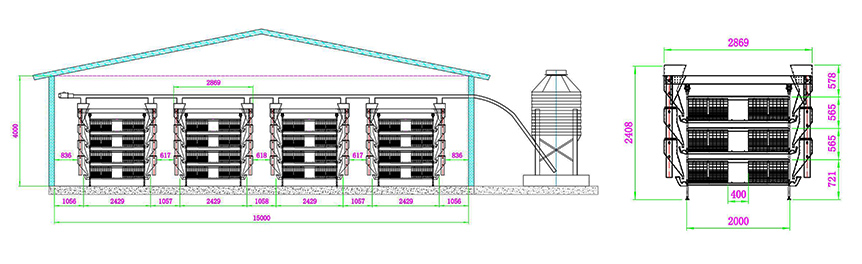

If you plan to raise 10,000 laying hens

Then your chicken farm needs to be 46 meters long, 11 meters wide, 11 meters high and 3 meters high.

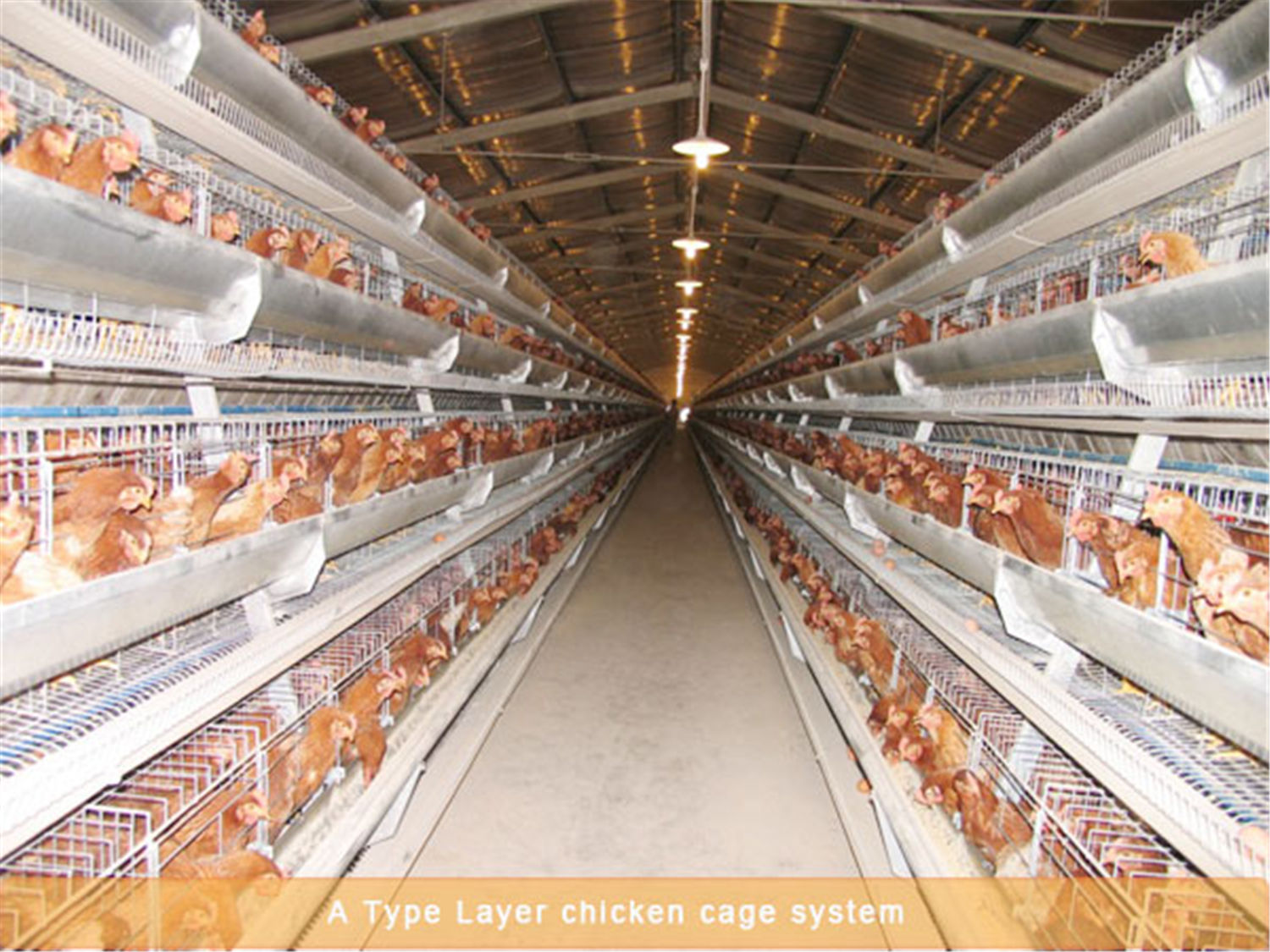

Use A-type layer chicken cages. One group can hold 160 birds.

Three columns, 21 groups. A total of 63 sets are required. Can accommodate 10080 birds.

Layer battery cages raise poultry at suitable densities. Allows hens to lay more eggs in enough space. Our products are designed to better suit the needs of the hen, while maintaining cost-effective production.

Ventilation

It is very necessary to develop a chicken house ventilation for intensive farming. Buildings with open sides are ideal, otherwise cross ventilation should be allowed at bird level in the form of floor level entrances oriented to allow prevailing winds to blow across the width of the building. The air mass between the side walls of the poultry house resists movement, even through open buildings. The wider the building, the more resistance it has to air flow.

Poultry farmers are advised to choose automated poultry environmental control systems: fans and wet curtains. For poultry to grow in a comfortable environment even in hot weather.

Constant Light

A well-lit house is essential. A dark house can lead to sleepy, inactive, non-productive birds. Light is important for feeding because birds identify food visually. This is especially important for centrally managed day-old chicks, which require very bright 24-hour lighting during the first week of life.

The above are the requirements for building intensive poultry farm shared by poultry equipment factories. This article mainly analyzes the three points of chicken farm space, ventilation and sufficient light. Hope to be able to help everyone.