How to make chicken disinfection in the chicken house more scientific

- Published in Chicken cages

- Be the first to comment!

- Read: 3602 times

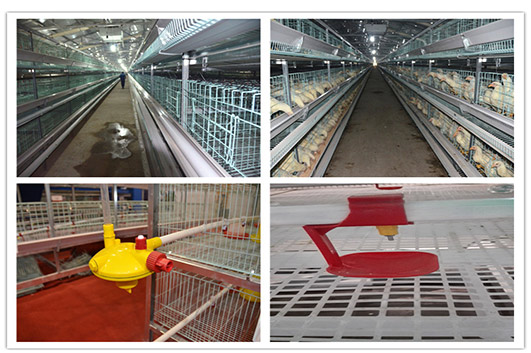

In the process of broiler chickens in chicken battery cage for broilers , chicken disinfection is a work that every farmer must pay attention to. The existence of pathogenic microorganisms in the houses of each farmer, especially when the weather is hot, is microbial reproduction. In a good period, it will directly affect the health of the flock. Therefore, reasonable and effective disinfection can provide a hygienic growth production environment for the flock and reduce the prevalence of the flock. Therefore, how can the farmers be more scientific and effective? Let me tell you something.

1. Clean the house before disinfection: Before the farmers are disinfected with the chicken, they should pay attention to the thorough cleaning of the roof, walls, chicken house passages and dust on the chicken battery cages . Improve disinfection and save drug use.

2, choose high-quality disinfection drugs: farmers should choose to use broad-spectrum, high-efficiency, strong sterilization effect but no toxicity, no irritating, no residue, and less corrosive to metal and plastic products. The disinfectant, farmers can choose according to their actual situation and local varieties.

3. Scientific preparation of disinfectant: When formulating disinfectant drugs, farmers should pay attention to selecting deep well water or tap water with less impurities, and pay attention to the water temperature control at 30~45 °C. Another important point is that the stability of the disinfectant medicinal water after dilution is worse, so the farmer must be ready to use now, once used up, the prepared disinfectant can not be stored.

4. Selection of disinfection equipment and correct spraying: When selecting disinfection equipment, it is recommended that farmers can choose high-pressure power sprayer or knapsack sprayer. When spraying, spray the circle above the chicken house. At 80 to 120 microns. If the fog is too small, it can easily be inhaled into the respiratory tract by the chicken, causing pulmonary edema. In severe cases, it may also induce respiratory diseases. However, if the fog is too large, it may cause uneven spray and increase the humidity of the house.

5. Master the frequency of spray disinfection and spray volume: Under normal circumstances, it is recommended that the farmer's chicken house can choose to disinfect the chicken 2 to 3 times a week. Farmers should not carry out chicken spray disinfection during the brooding stage, but they can be disinfected with chicken after 1 week of age. However, it should be noted that the general amount of spray is calculated according to 30 to 50 ml per square meter, the amount of chicks sprayed is less, and the amount of medium-large chicken is more.