How Intensive Poultry Farming Can Keep Farm Dust Down?

- Published in Poultry raising equipment

- Be the first to comment!

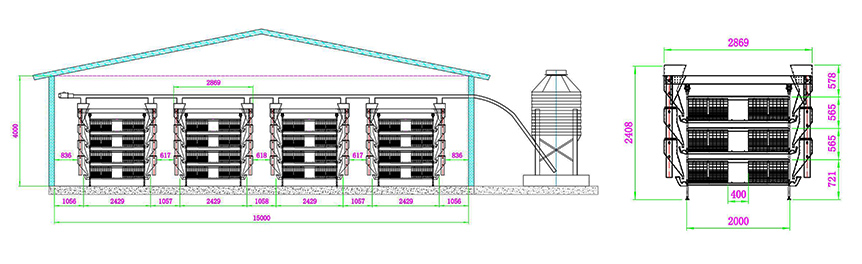

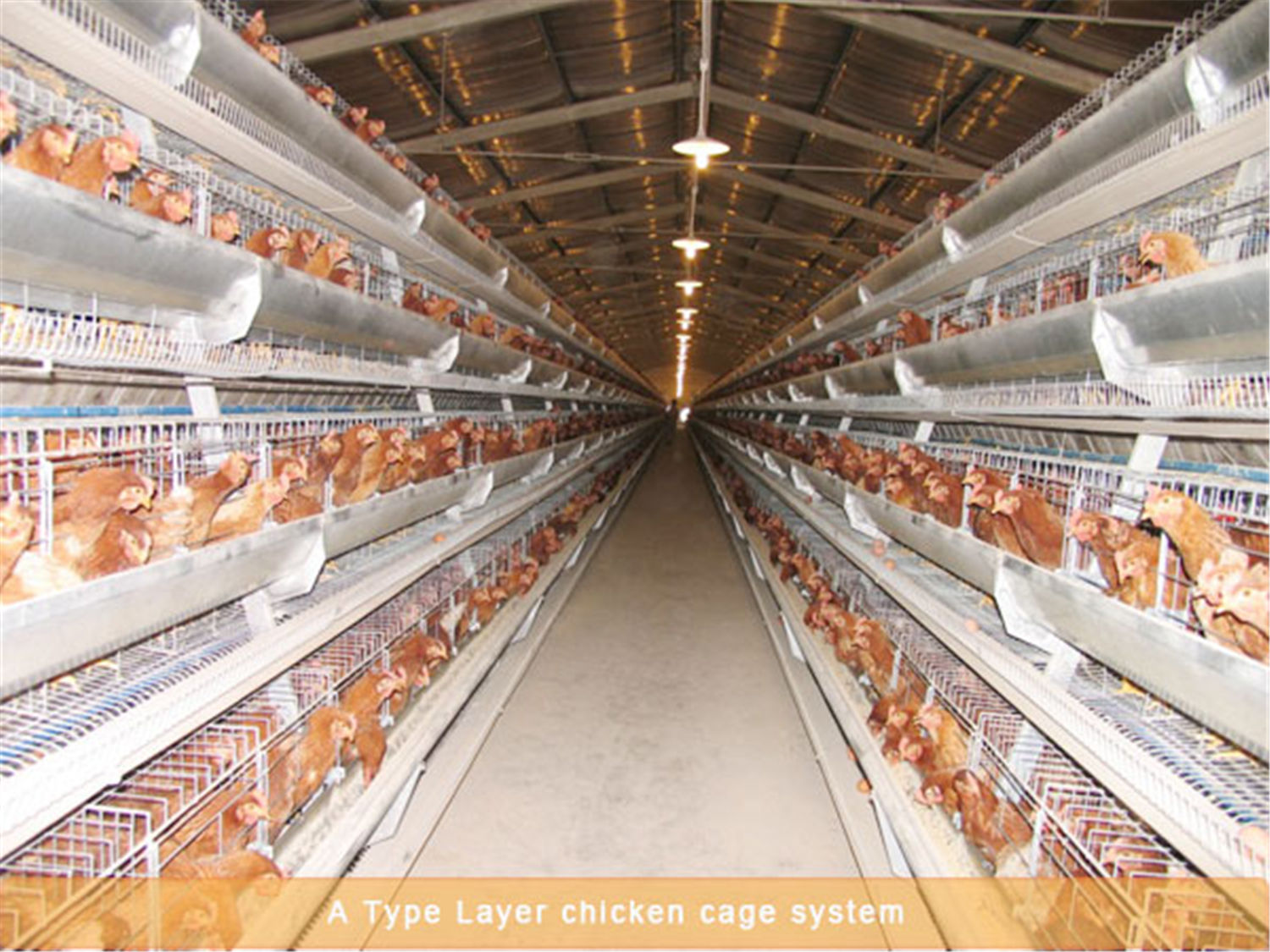

The environment of the chicken farm is related to the growth of the chicken flock. Therefore, it is very important to control the hygiene of the chicken house. The dust in the chicken farm mainly comes from the dust in the battery layer cages chicken house, as well as the fallen feathers, feed powder, etc. These dusts not only affect the staff in the chicken house, but also have a great impact on the health of the flock. So how to reduce dust in caged chicken houses?

Sprinkle water on the ground

The most dusty place in the coop is the ground. Sprinkling water on the ground can reduce dust flying. After spraying water on the ground, and then remember to mop the floor. Just like cleaning our home, creating a good living environment for poultry.

Reduce breeding density

The higher the breeding density, the more dust. In order to effectively reduce the dust in the chicken house, we can appropriately reduce the density and also reduce the dust content in the chicken house. After all, there is a lot of dust coming out of chickens, such as feathers, feed meal, etc. However, this also takes into account the overall farming efficiency.

Adopt automated poultry farming equipment

Automated manure removal systems in automated poultry farming equipment can now transport chicken manure outside the house. Not only the odor of chicken manure in the chicken house is reduced, but also the chicken feathers can be transported outside together. The sanitation of the chicken house is guaranteed.

Clean the chicken farm often

Dust doesn't appear all at once, it builds up over time. So dust reduction is a long-term continuous process. In the process of raising chickens, it is necessary not only to clean the chicken coop frequently, but also to clean the outside environment frequently. With less dust outside, the dust in the house will naturally decrease.