How to improve the growth rate of broilers?

- Published in Poultry raising equipment

How to quickly increase the growth rate of broilers using automated chicken farming equipment has always been a concern of farmers. The slow growth rate of broilers has seriously affected the economic benefits of farmers. The following authors will introduce them in several aspects!

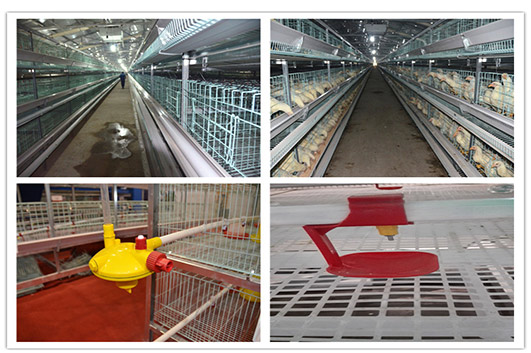

In the fully automatic equipment, we use broiler cages to place 2-3 chickens in each broiler cage, then install the food trough and sink in the position of the broiler cage, through the automatic feeding mechanism and the water supply system, on time The poultry diet is carefully taken care of, so that all poultry in the feeding process can get enough food and water, and at the same time can get a lot of growth nutrition.

The broiler cage is made of high-quality, smooth galvanized material, which can well control the occurrence of problems such as foot injury and infection during the movement of poultry. At the same time, it can easily enter the feces collection device from the bottom of the cage when the feces are produced. The treatment of chicken manure can be conveniently carried out to ensure a hygienic environment in the breeding environment.

The use of broiler chicken cages for breeding is also good for the isolation of chickens on the one hand, preventing the infection of the entire poultry when individual poultry is morbid, ensuring the overall hygiene of poultry and greatly improving production efficiency.

Temperature control:

1. Place the thermometer (height and quantity) reasonably. In the standardized chicken house, the length and width of the house are large. The temperature in the house or the north and south sides of the house is inconsistent. It should be noted that the thermometer is placed reasonably, and a thermometer is placed in the east, middle and west of the house. Get the average temperature in the house.

2, high temperature season cooling measures (wet curtain): high temperature season can reduce the temperature inside the house through the wet curtain, at the same time should pay attention to the opening time of the wet curtain, to avoid the temperature in the house is too low or the temperature in the house is inconsistent, resulting in chicken cold.