Advantages of using modern broiler cage farming equipment

- Published in Chicken cages

Broiler cages are essential equipment for modern farming users to breed broilers and brood. The use of broiler cages by farmers can save feed, promote egg production, reduce costs and gain more benefits. This equipment can also be designed and manufactured according to the size of the culture site of the farmer. So what are the advantages of using modern broiler rearing equipment?

In order to raise a good chicken house environment, it is inseparable to choose high-quality chicken and scientific farming methods. Especially in the temperature, humidity, density, ventilation, lighting, feeding and scientific control, is a necessary factor for the success of farming. These are inseparable from the assistance of farming equipment. The advantages of using a broiler cage are as follows:

1. Using broiler cages to breed broilers, you can make full use of the chicken house area and raise more chickens, and the cage area is relatively small. This will reduce the footprint and raise more chicken. The use of broiler cage culture can isolate the flock from the feces, thus avoiding contact with the flock and reducing the spread of disease.

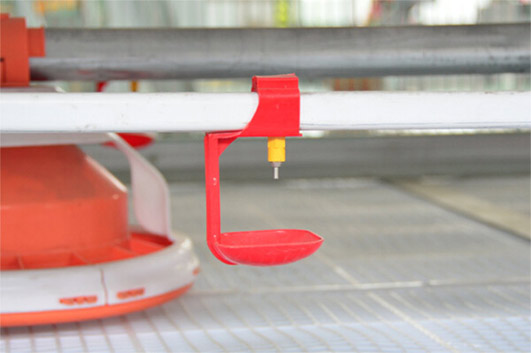

2. It can install automatic feeding equipment, automatic water dispenser, automatic cleaning equipment, and modern ventilation and cooling equipment. The automatic feeding equipment is specially designed for the loading equipment of the cage type. It has uniform feed feeding, small loss, convenient operation and convenient steering maintenance. Drinking fountains can save water and prevent bacterial contamination so that broilers can automatically drink water, and also ensure the environment inside the house and reduce disease.

3. It can reduce the intensity of manual work, reduce labor and improve work efficiency. There is also a modern pure-based fuel boiler, which has the characteristics of fast temperature increase, environmental protection and economy. The development prospects of modern poultry farming equipment are excellent.

The above is the author's advantage of using automated poultry farming equipment, I hope to help everyone.