What should be considered by layer cage farmers in the process of raising chickens

- Published in Chicken cages

- Be the first to comment!

- Read: 2949 times

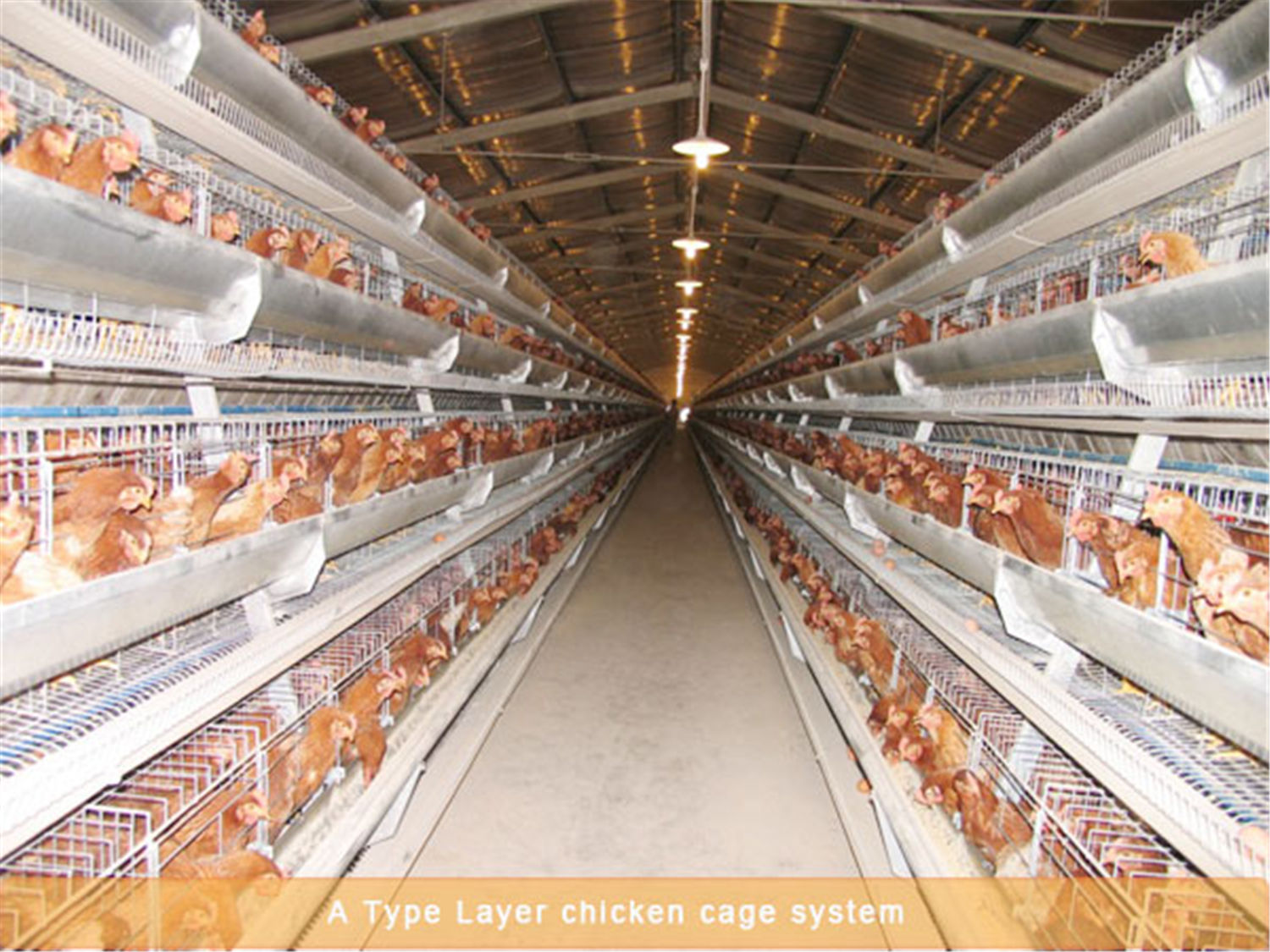

Nowadays, the first choice for farmers to raise chickens is to raise chickens in layer cages, because the use of layer battery cages for intensive chicken raising is not only more scientific, but also conducive to management. In addition, modern people's demand for eggs has been increasing, and many people are willing to join the breeding industry, but what needs to be considered?

- Farmers must be diligent and careful when raising chickens. Because in the process of raising chickens, farmers must observe the flocks. Once sick or unhealthy chickens are found, they can take immediate measures to avoid greater losses.

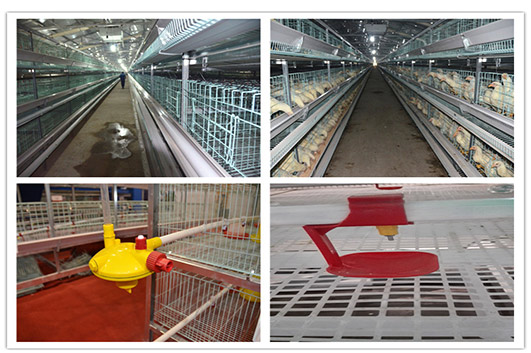

- Farmers must have a moderate scale. When choosing the number of chickens, farmers should base their chickens on the area of their chicken house and the space occupied by some chicken-raising equipment that needs to be selected. Otherwise, the density of too large or too small will affect the economy of the farmers. The level of benefit.

- The principle of reasonable chicken density. The use of modern layer battery cages for intensive chicken breeding has maximized the scale of breeding compared to flat breeding. A moderate density not only grows quickly and feed conversion rate is high, but also is conducive to the healthy growth of chickens.

- Farmers must have the idea of disinfection and immunity. The chicken farm is also a bacteria farm. If the farmers don’t pay attention to killing the bacteria, they will only broadcast it to the chickens, which will affect the health of the chickens. The effective way to kill the bacterial pathogenic microorganisms is frequent disinfection. Therefore, farmers must raise chickens on a large scale. Do a good job of disinfection to prevent the spread of pathogens to the flock from the source. In addition, immunization is an effective way to prevent diseases, so farmers must do a good job of immunization according to the epidemic and disease in the area.