With the development of the modern chicken breeding industry, a number of mechanized and semi-mechanized chicken farms have been built in various parts of Nigeria. The scale of professional households in urban and rural chicken farming has also gradually developed from small to large. To raise chickens, you must first have a chicken house. The chicken house was built to avoid wind, rain and sun, to create a good living environment for the chickens, to maintain a good physical condition throughout the year, and to achieve the desired level of laying. For the professional breeders, the first is to use their existing free houses as a chicken house, and the second is to use the idle land to build a new house, whether it is to use the old house or to build a new house. All must have the following conditions.

1. Conducive to ventilation and ventilation: Due to the high density of chickens, it is necessary to promptly discharge the dirty and harmful gas in the house, including the discharge of hot air and moisture in summer to ensure healthy living and normal production.

Professional farmers raise chickens. Generally, they can only use the natural wind and the temperature difference between the inside and outside of the house to form a burning airflow for ventilation. Therefore, it is best to have the house facing north and have front and rear windows and skylights (or wind phase). Windows and hoods should be able to be opened and closed to allow for airflow adjustments based on books from different seasons.

2. Conducive to the control of light: all growth and development stages of the chicken require a certain amount of illumination time and a certain light intensity. Especially for laying hens, the importance of light is more prominent, because egg formation and light are closely related. For natural light, using it can reduce the cost of raising chickens and is an aspect of utilization. However, the natural illumination time does not necessarily coincide with the needs of chicken growth and development. Therefore, in addition to the requirements for lighting conditions, the chicken house should also take into account the equipment that can control the natural light entering the house when the chicken needs a shorter light time. When the chicken needs a long light time, it can have equipment to supplement the light.

3. Good thermal insulation performance: The chicken house generally maintains a suitable temperature in the spring and autumn, and it is necessary to take measures against cold and heat during the temperature change season. Because the temperature of the temperature has a direct impact on the performance of the chicken. If the weather is too cold, you can warm the stove so that the house is not lower than 8C. When the weather is hot, you should open the windows on both sides to facilitate ventilation. You can also plant some grapes on the south side of the chicken house or take the beans to cover the shade. However, keep a distance of 2 meters to 3 meters with the house, and do not be too dense, so as not to affect the ventilation inside the house. This not only beautifies the environment, but also prevents radiant heat.

4. To be effective in epidemic prevention and disinfection: the establishment of a disease-free chicken farm is a reliable guarantee for the development of the chicken industry. In particular, raising large-scale chicken farms should pay more attention to this problem. Both the chicken farm and the entrance and exit of the chicken house should be equipped with a disinfection tank, and keep the pool containing effective disinfecting drugs so that the vehicles can be disinfected. The disinfection tank can hold 1% of the comel solution or 2% of the caustic soda. Spray disinfection can be used with 1% of neostigmine or 3% of clindaline. Small chicken farms require at least a disinfection tank. It is best to use concrete floors to treat feces and quarantine.

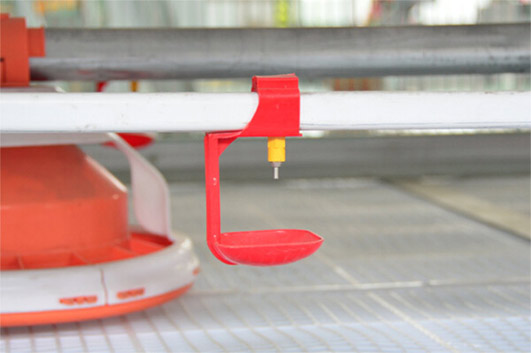

5. Conducive to the use of space: especially the new chicken house, before starting construction, according to the size of the poultry farming chicken cage and chicken rack used, calculate the size of the chicken house to make more reasonable use of the chicken house space.

In short, the construction of the chicken house should be based on actual needs, choose the style. It should not only meet the physiological characteristics of chickens, but also enable chickens to grow rapidly and improve productivity. It can also meet the principles of durability, easy management, easy cleaning and disinfection, and improved work efficiency. At the same time, it is necessary to adjust the design of the chicken house reasonably according to local conditions and reduce the construction cost of the chicken house building. In the areas where conditions permit, the use of advanced chicken houses suitable for the production of mechanized poultry farming equipment should be used as much as possible to promote the smooth development of the chicken raising business.