Intelligent lighting for laying hens cannot be less

- Published in Chicken cages

- Be the first to comment!

- Read: 3486 times

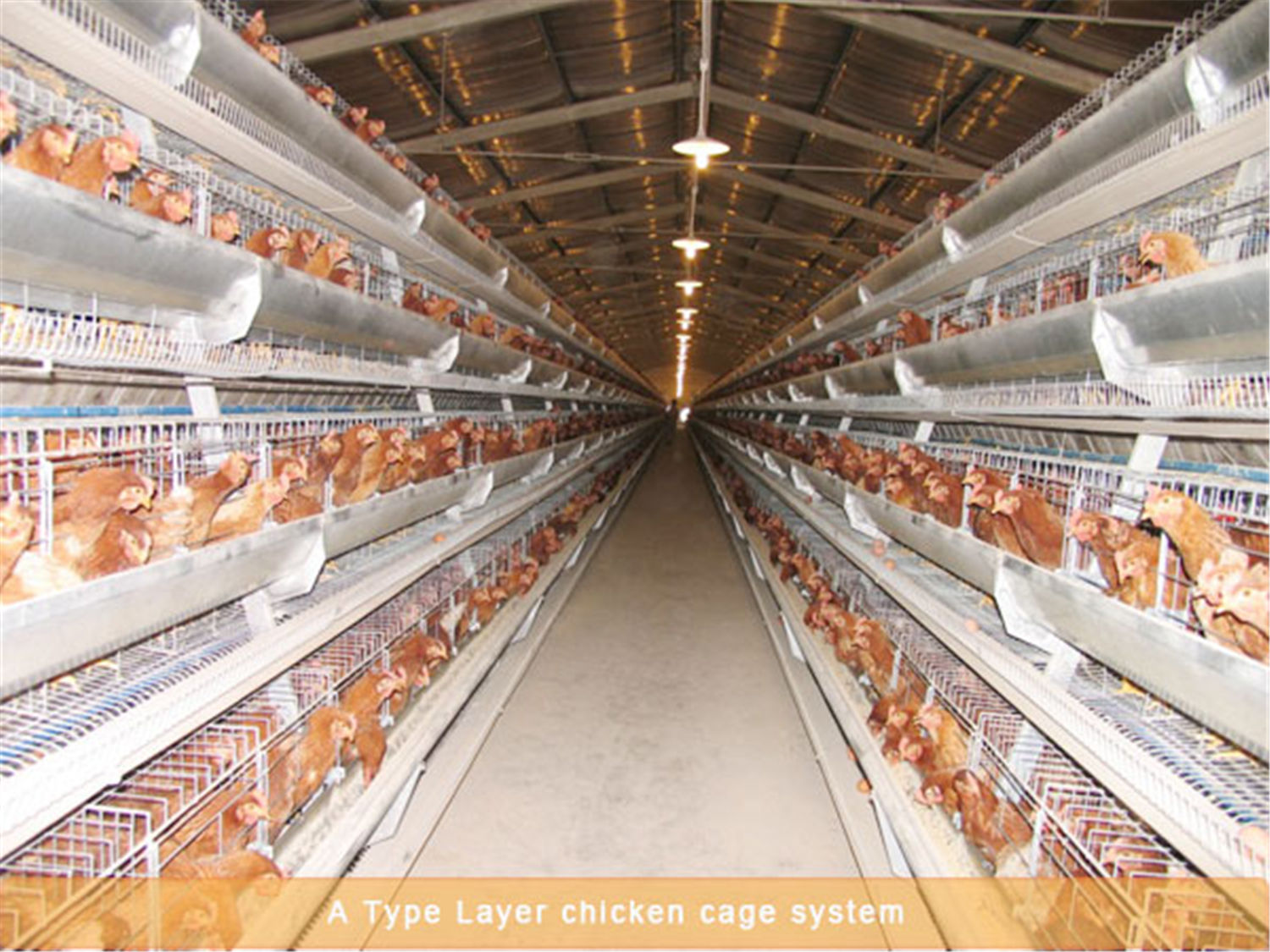

As we all know, light is an indispensable key factor in poultry production. Proper lighting conditions have a positive impact on the growth and development of poultry bodies, and can promote the normal development of the body's genetic potential. With the current economic profit of laying hen farming continues to decline, because laying hens are raised in chicken cage. In view of the important role of light environment in the growth process of laying hens, how to reduce the cost of light in production, ensure the healthy growth and development of chickens, and improve the survival rate has become a key technology.

The traditional lighting technology is a constant incandescent lamp or LED lamp. As the chicken ages and production conditions change, the light intensity and light time must be adjusted manually. In the intelligent lighting system for layer breeding, cold cathode energy-saving lamps are used as the light source, and it is equipped with light sensors and intelligent control terminals, which realizes the light effect of simple management and energy saving.

Intelligent lighting technology is based on the organic combination of cold cathode fluorescent lamps and intelligent control. This technology adds sensor systems, intelligent control systems, cold cathode fluorescent lamps and other equipment to the breeding process, and through the automatic monitoring and intelligent regulation of the lighting environment in the poultry farms, it finally realizes the scientific compensation in the poultry farms. Light.

The cold cathode energy-saving lamp used in the technology has rich colors, small tube size, light weight, simple structure, quick start at low temperature, small surface temperature rise, high brightness, high efficiency, and easy processing into various shapes (straight tube shape) , L-shaped, U-shaped, ring, etc.), long service life, good color rendering, uniform light emission, etc. When reaching the same lumens, the power consumption is only about 10%-20% of incandescent lamps; compared with fluorescent lamps, the luminous efficiency is slightly lower, but the life span is four to five times that of fluorescent lamps, and the mercury content in the tube is extremely low or It is completely mercury-free, avoiding the pollution problem of mercury vapor; compared with LED lamps, it has good color rendering performance, no glare, and low price.

The light time and intensity of brooding period, rearing period, and laying period are different. In the past, the replacement of light bulbs was done manually in the production process. And this technology uses an intelligent controller to adjust the frequency of alternating current, thereby changing the light illuminance changes, achieving a light bulb "fixed" the entire production process, greatly reducing the human and material input in the breeding process. Effectively increase production capacity, the application of intelligent lighting system can increase the laying rate of laying hens and the rate of weight gain of broilers by 1%, which can bring considerable economic benefits.